|

||||||||||||||

|

||||

This page is under construction and will contain a list of questions and answers concerning the use of Signal Research's Digital Block Control Roadmaster System. I am a current user of the RM - DBC system and have received several e-mails concerning the use and hookup of the system. I was thinking about opening a Yahoo Groups forum for this discussion but I really do not have much time to moderate. I will discuss with SR the possibility of opening the group and having a link posted on their front page. I do not know how much direct involvement SR will have in the group at this time. So for now I will be going through several archived e-mails and posting the questions and answers I have compiled over the past several months. Please let me know you interest in opening a Yahoo Groups site. KLWZScale |

|

||||

|

|||||

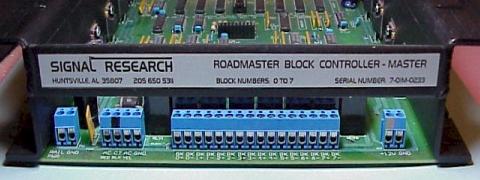

Where can I find additional information on DBC or the Roadmaster System discussed here? The first and foremost authority on the Roadmaster System (RM) is Signal Research itself. |

||

The following questions can be answered by visiting the Signal Research Web Site Frequently Ask Questions Web Page How does DBC work? What does the system consist of? Exactly what is the Auto-Nudger? How does the system know where each train is? How does the system tell the difference between each train? Is each train controlled independent from the other trains? How many trains can the Roadmaster DBC system handle? What about helper engines? What is the output of the Roadmaster and how safe is it? What extra wiring is needed for crossovers and reversing loops? How hard is it to hook-up and setup? I already have my layout blocked and use conventional block toggle switches to route power. How easy is it to convert to the Roadmaster system? I have some engines that require very little power to start and other engines that require nearly half throttle before they start. How does the system handle or compensate for these engines? Some of my trains are very long freights and others are high speed passenger trains. How does the system control starting and stopping of each train? What kind of circuit protection is provided? I have a large, twenty-four track staging yard. Do I need to dedicate three Block Controllers to this yard? Wouldn't this be very costly? I'd like to control one train manually, but still have several others running. Can the system handle some trains on manual and others on automatic? How long is each block? Does each block need to be the same length? Do I need to add resistance wheels to my rolling stock for detection? |

||

Questions I've received and tried to answer for others |

||

How do you wire the Marklin Z-Scale Turnouts for use with the RM system utilizing Momentary toggle switches? I would also like to utilize Bi-polar LEDs to indicate the direction of turnouts on a Control Panel. Click here is see how I performed this task with the KLWZScale I Layout. |

||

What does the block layout diagram and program for the RM system look like for the KLWZScale I Layout look like? Click here to see the block diagram and program table. Click here to see the KLWZScale I Layout and additional Roadmaster being wired to the layout and control panel. |

||

From Fig.6 of the RM Instruction Manual, Layout Blocking Example. Are all lines set up initially for one direction only (say east) and then direction changed as per para. 7.3, or can east and west be programmed as east and west if the predominant traffic is east or west. The setup of line direction really does not relate to true E/W of the line. They are just an arbitrary set of directions. Very easily could have been labeled North/South or East/South does not matter. What does matter is that you stay consistent with your nomenclature and wiring. What do I mean? What sets up the E/W (what we will call E/W for now on.) direction of the track is actually the wiring. What you are doing is saying if my loco goes to the right when I power on the throttle (not using DBC) this will be the East direction for example. Now look at your wiring to that track. You should have a red and black wire (or two other colors) one wired to each rail. Now determine which wire goes to which track. If the red wire is on the right rail when your loco is moving forward you need to say that anytime the primary direction of travel is forward on a certain track you need to wire the red wire to the right rail and call this direction East. The Roadmaster System (RM) only wants to know what is the polarity of the lines. Is the red wire on the right rail or left rail in the block that is next in line. You can layout your track so that every other block is East then West but this has no logic. You will just get very lost while programing the RM to your layout. I would try to make most of the primary direction of travel be wired all the same way. If you do reverse the wires Red on the left rail either on purpose or not when you program the RM you will just say yes when asked if there is a direction conflict. What this tells the RM is that it needs to reverse the actual wired polarity of the rails in the next block. Very similar to you flipping the direction switch found on many model RR throttles. But when you slide the switch you reverse the loco. The only reason it goes in reverse is that you switched the polarity of the rails. But with the RM to keep the train going in the same direction and at the same speed etc. it needs to switch the polarity of the next block to match the current block. It does this in micro-seconds and you never can tell when it happens if the layout is programed correctly. |

||

Fig.6 again. Blocks appear to be arbitrary and do not take diamond crossings into account e.g. B1/B13-B14 and B1/B7-B8. I ask this because all my diamond crossings are isolated at each 4 entrances/exits (both rails). I think SR programed the layout this way to minimize the number of blocks required. You want to maximize the number of normal blocks and minimize the number of short block. Short blocks are bad because in most situations you will be occupying both the normal blocks on either side of the short blocks. And therefore 1 train takes of 3 blocks of you layout. (My layout had two short blocks.) The blocks were definitely not set arbitrarily they were placed to minimize the number of blocks and short blocks. You do not have to split your layout into blocks at every turnout. Turnouts can be located within a block. You can program your diamond crossings many different ways. I do not know if I can give help on what you may want to do without seeing a layout. I will revisit when I see your layout. |

||

Facing points/turnouts with live frogs must have complete breaks between them as per diamond crossings - see 2 above. My routes will be controlled by switches (see intro). Therefore as a crossing or point/turnout is specifically isolated does this mean that it has to be the start /end of a designated block or can I determine the length of a block myself ? (see next question) You can determine the length of the block yourself. The RM system works off feed back from your switches or switch machines. The RM needs to know the direction of the turnout. This is what determines how the next block needs to be energized. |

||

Are all block lengths determined solely by the criteria of length of train + stopping distance irrespective of the number of completely isolated points/turnouts and crossings within a potential block length ? Block lengths can be made any length you like. Block lengths are determined by the location of isolation joiners/splitting the rails. Lessons learned from my layout I would like to have broken up each main run / loop of track into at least 4 or 5 blocks. What this allows you to do is run two trains very smoothly around the same loop without them having to stop or slow to much (all done automatically by the RM) since the block ahead is occupied etc. it is a case of cat and mouse. It is best to try and make blocks at least as long as the longest train plus stopping distance but it is not required. My layout had many blocks less than the length of a potential train. Turnouts and crossing can be located within a block and you do not need a block at each and T/O. But at least one of the T/O directions will require a block to be made. (trying to say that a turnout can be used as a straight or curved piece of track within a block but the diverging route will need to be isolated at some point. blocks do not need to be isolated right at the turnout. Isolations can happen beyond the T/O points/frog ends. |

||

I've been looking on your web-site at your block plan and block data sheet. They have been a great help in understanding the situation. However, I am a little confused over ' direction conflicts '. Do these only occur in reverse loop situations ? A direction conflict can occur without a reverse loop. The direction conflict is determined by the wiring to the rails. If for some reason you switch the side of the rail the "Red" wire is on in your current direction of travel then you will need to say there is a direction conflict. |

||